About

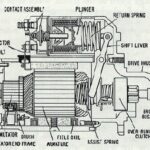

Custom Rebuild and Return (R&R) Service

Rely on our Custom Rebuild and Return (R&R) services for fast turnaround and reliable performance. Skilled technicians combine over 100 years of experience to repair starters, remanufacture water pumps, and restore DC motors to peak efficiency. From initial inspection through final testing, our team ensures precise workmanship and attention to detail.

Parts We Rebuild and Restore

Our expertise includes:

-

Starter rebuild service for cars, trucks, and heavy equipment

-

Water pump rebuilding for automotive and industrial systems

-

DC motor repair and restoration

-

Alternator rebuild service for all vehicle types

-

Distributor rebuilding for accurate ignition timing/Discontinued

-

Generator rebuild service for dependable power output

Precision Testing and Diagnostics

By utilizing the latest state-of-the-art diagnostic equipment, we identify issues before starting repairs. Technicians perform thorough performance tests after rebuilding, confirming every part meets or exceeds OEM standards. Consequently, your rebuilt component performs like new—or better.

Full-Service Machine Shop Capabilities

Our in-house machine shop restores worn or damaged parts with exact precision. Moreover, this capability supports both automotive remanufacturing and heavy-duty industrial rebuilds. We combine modern technology with proven craftsmanship to deliver consistent, long-lasting results.

Quality Built to Last

High-grade replacement parts and strict assembly standards ensure every rebuild offers improved durability, longer service life, and enhanced efficiency. In fact, many customers find our rebuilt units outperform the originals.

Warranty-Backed Repairs

You benefit from strong warranty protection:

-

One-Year Warranty on standard automotive parts

-

Six-Month Warranty on heavy-duty and industrial parts

Why Customers Choose Us

Five core values—Quality, Service, Innovation, Integrity, and Pride—drive every rebuild. For these reasons, clients trust us for fast, dependable repairs that last.

Get Back to Work Faster

Selecting our Custom R&R rebuild service delivers expert craftsmanship, advanced testing, and proven results. Moreover, we provide a clear price quote before beginning work. Ultimately, we rebuild it, return it, and keep your operation running at full strength.

Quality | Service | Innovation | Integrity | Pride

Attention Installers

Before installing alternator check the following related items:

- Battery: Check for faulty or weak battery. Battery must be secured tight inside the battery holder.

- Fully Charged Battery: Make sure that the battery is putting out 12.6 volts and is fully charged. Load test battery to ensure it will hold charge.

- Correct Battery: Make sure you are installing the correct battery for the vehicle with the necessary cold cranking amps.

- Battery Cables: Check for proper connections, corrosion and wear. Cables can be tested by verifying the voltage drop doesn't exceed 1/2 volt from end to end.

- Belts: Check belts for cracks, polished wear and alignment.

- Belt Tensioners: Check for proper tension and for binding.

Remember: Do not jump-start another vehicle while the battery is still connected to the electrical system.

Before installing alternator you must be certain the battery is fully charged and load tested

Remember: Never remove the battery cable while the engine is running to check charging system. This will cause damage to the alternator and computer system.

NOTE: Alternator is not a battery charger. It is designed to maintain a fully charged battery.

67% of all alternator failure is due to faulty or weak battery.

14% of all alternator failure is due to poor connections, fusible links, faulty battery cables and bad grounds.

9% of all alternator failure is due to belt wear or tensioner related.

6% of all alternator failure is a result of jump-starting another vehicle

Attention Installers

Alternator IS NOT A BATTERY CHARGER!

IT IS DESIGNED TO

MAINTAIN A FULLY CHARGED BATTERY ONLY

NOT TO RECHARGE A DISCHARGED BATTERY

BEFORE INSTALLING the alternator, CHECK the condition of the vehicle's BATTERY as follows:

1. If the voltage of the battery is BELOW 12.4 VOLTS, RECHARGE TO 12.4 VOLTS or higher.

*Voltage at the battery and back of alternator B+ post should read 12.4 to 12.6 volts before starting engine*

2. If the battery is 30 MONTHS OLD or OLDER, it should either be PROFESSIONALLY LOAD TESTED

or have a high quality NEW BATTERY INSTALLED BEFORE STARTING THE ENGINE.

UNLESS THESE PROCEDURES ARE FOLLOWED, DAMAGE TO THE ALTERNATOR OR STARTER MAY OCCUR, WHICH MAY VOID WARRANTY.